Introduction

Hydraulic valve bodies in many varieties are one of the most widespread industrial components in cast iron.

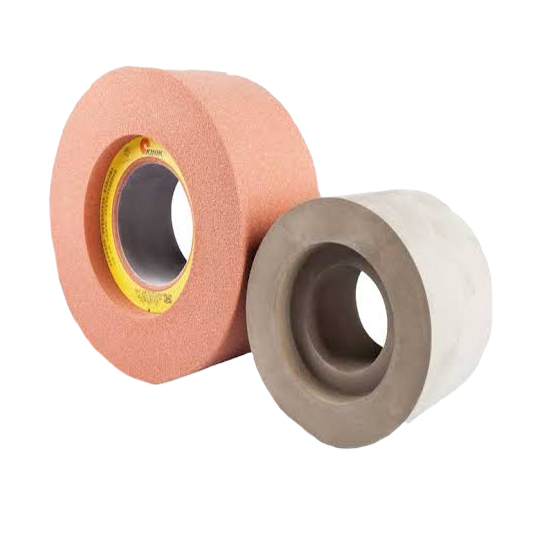

Cutting tool solutions for hydraulic valve bodies

This brochure focuses on tooling solutions for the ma- chining of hydraulic valve bodies in cast iron.

Ring-free machining

Rings produced in the bore by the rough pass reamer is a common problem when machining spool bores.

At the cutting edge

Our intensive research and development continuously improve the tool solutions for the benefit of our custom- ers.

Welcome to Murthy Industries

Murthy Industries manufactures, distributes and services tools for machining, primarily for The metal, woodworking, automotive, aerospace, power generation and fluid power industries. The technology centre in Bangalore focuses on euective solutions for production. The tooling concept comprises standard and customised tools, RENEW® tool maintenance, coating and optimisation guidance. The Shefleld branch specialises in supplying inserts, standard tools and related tool solutions to the industrial market in the India, including the general machining, aerospace and medical industries.

The company was established in 2017, services all of the INDIA, and is part of the Murthy Industries, founded in Bangalore and originally named Murthy. In 2017, all activities were acquired by Japan-based. This has created an even stronger company with a larger range of products, a wide network of distbutors all over the India, and an ambitious growth plan.

The Aim Is To Reduce Your Unit Costs

By implementing improved tool technology and by reducing the number of tools needed, the part quality will be improved and machining time will be reduced while maintaining a se- cure process.

Good cooperation has more than one winner

We believe in close and long-term cooperation with our custom- ers. By means of mutual knowledge sharing and development ef- forts, our customers receive more than just a top quality cutting tool. Our optimisation experts thoroughly analyse the manufac- turing set-up in a detailed and methodical way in order to im- prove the manufacturing process. We call this ‘Systematic optimi- sation of Production’.

Optimising The Process Strategy

Increasing cutting data with helix tools

One of the general optimisation principles is to re- place straight fluted tools with helix tool solutions. combined with the c7 PLUS™ coating it is often possible to increase the cutting speed consider- ably while maintaining the same tool life time and machine wear.

Revealing the potential

Measuring the thrust force of each solution when running at the same cutting parameters reveals the optimisation potential. Applying the same cutting parametres, the thrust force is much lower when using the twist drill than the straight fluted drill. However, the correct runnning in of the tools is a precondition for getting the optimum benefit of the improved tool solution.

Increasing the cutting data

The cutting parameters of the twist drill are in- creased until the thrust force is equivalent to the original straight fluted solution. The result is that the cutting data can be increased by up to 248% (VF 3081 mm/min. / Vf 1241 mm/min.)

Competitiveness Through Reduced Production Costs

Through higher product quality and reduced machining time, we can lower your production costs. Learn more about our unique tool solutions, which are known to significantly increase productivity.

Valves

optimisation Total reduction of cycle time

35-70%Motors for work functions

optimisation Total reduction of cycle time

25-50%Steering units

optimisation Total reduction of cycle time

25-50%Email Id

sales@murthyindustries.com

Contact No.

+91-9878986545

Address

#616 , 14th Cross,15th Main, Sector-4, HSR Layout Bangalore-560102